Description

Product details

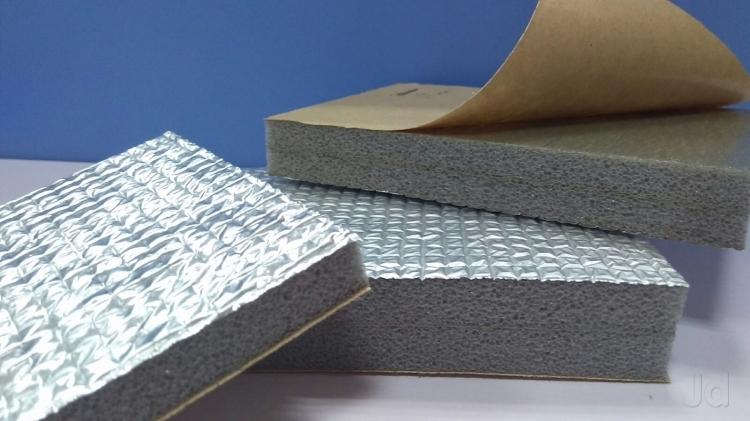

XLPE FOAM (CROSS LINKED POLYTHYLENE FOAM) The processing of cross linked polyethylene foam, which has a closed‐cell structure, has been investigated. In this study, two types of linear low‐density polyethylene (LL) produced by a metallocene catalyst were crosslinked by dicumyl peroxide (DCP). The expansion ratio of the foams decreases with increasing the DCP content, which is due to the enhancement of the elastic modulus. Moreover, the crystallization temperature Tc of the foams is also responsible for the expansion ratio. After expansion, the crosslinked foam with lower Tc shrinks to a great degree prior to the crystallization, which is attributed to the volume reduction of the gas in the cells. As a result, the expansion ratio decreases. The degree of shrinkage decreases with increasing the Tc, because immediate crystallization prevents the shrinkage. Density or “hardness” ranges from 2.0 lbs pcf (lbs per ft3) and extends to 30 lbs pcf. Thickness of the roll/sheet ranges anywhere from 1/32″ to 4″. Widths of the roll/sheet vary from our standard 60″ to as wide as 72″. (A typical roll diameter is approximately 36″.) Lengths of the roll/sheet ranges anywhere from 10 ft to 2,000 ft. Colors are classed within two categories. The standard colors are natural (the color of French vanilla ice cream), gray, charcoal, and black. Custom colors are available for an additional fee SAI INSULATION INDIA NO- 14, GROUND FLOOR, KALIKA NAGAR, ANDRALLI MAIN ROAD,NEAR PEENYA 2ND STAGE,BANGALORE - 58 Ajay 9738386050 9900190088 saiinsulationindia@gmail.com